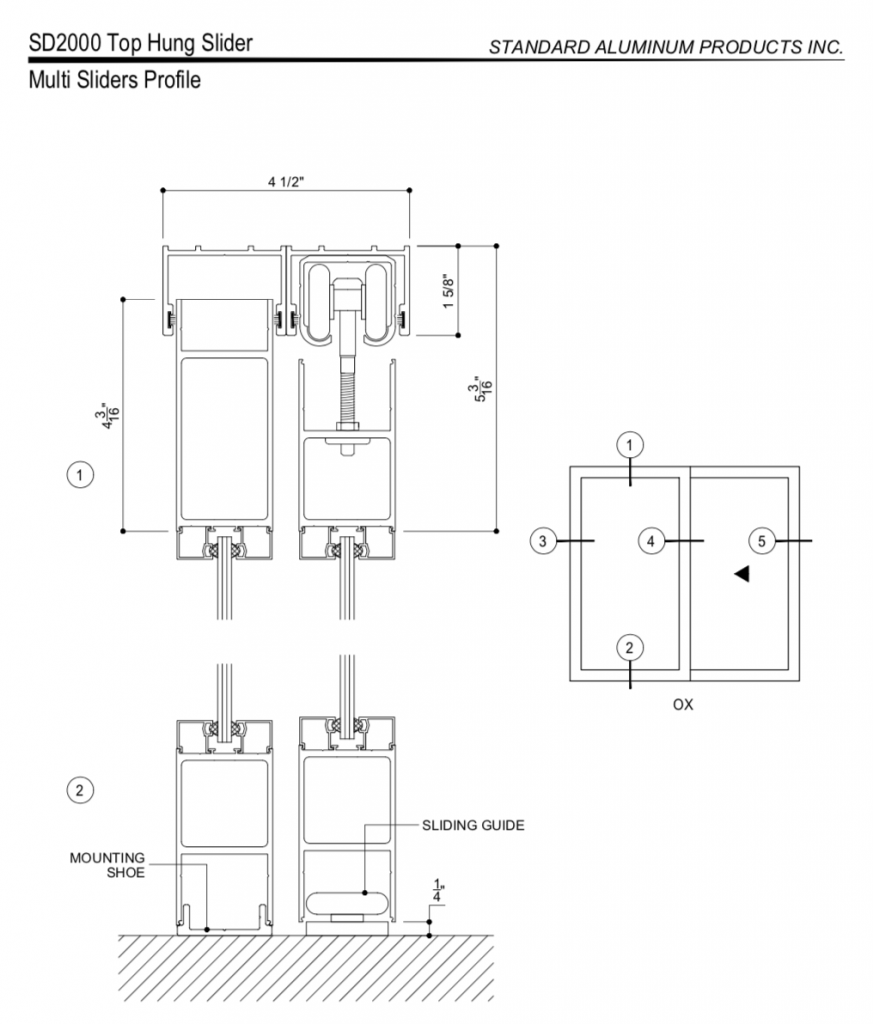

Design

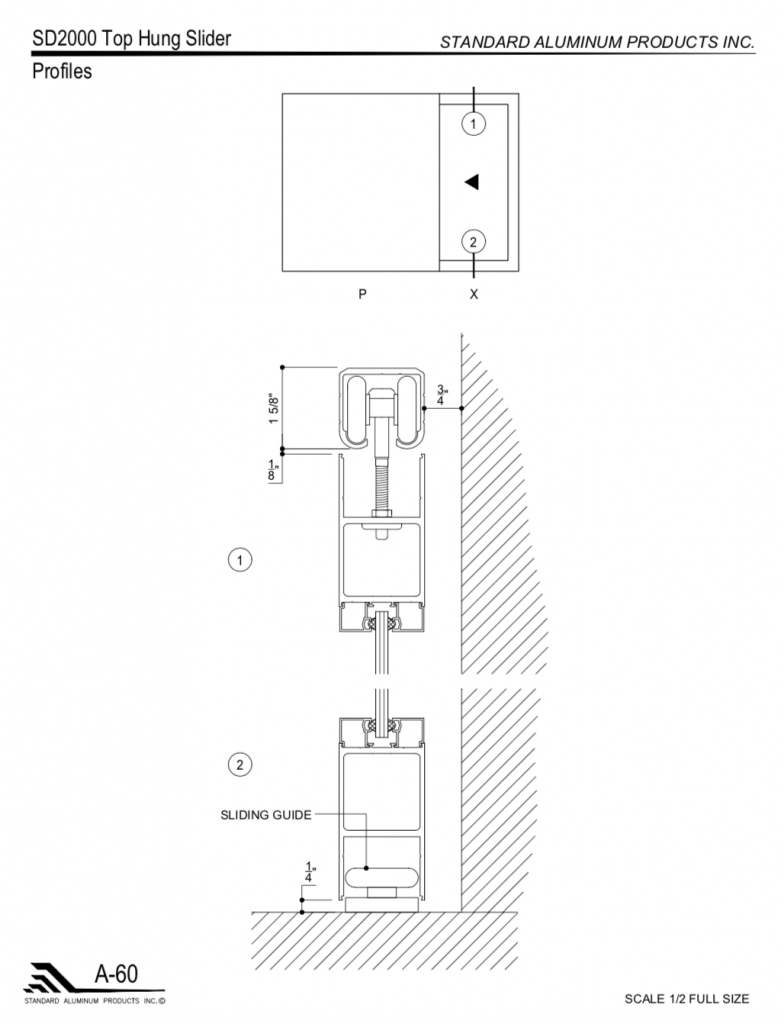

Top Rail Height 3.125″

Bottom Rail Height 3.125″

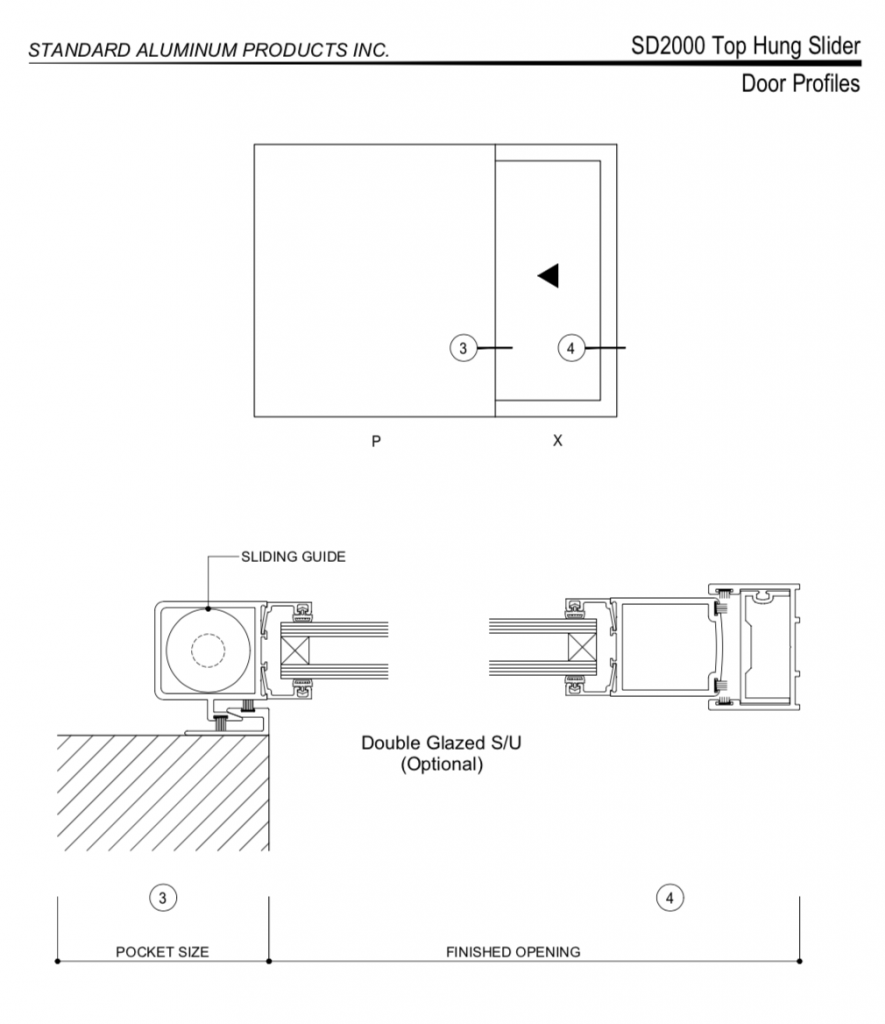

Stile Width 2.00″

Door Thickness 1.75″

Top Track/Jamb 1.625″

Glass stops available:

1. Square single glazing

2. Sealed unit glazing

General Description

Work Included: The glazing contractor shall furnish all necessary materials, labour and equipment for the complete installation of aluminum entrance doors, door frames and hardware as detailed on the drawings and specified herein.

Work Not Included: Structural support of the framing system, wood framing, structural steel, masonry and final cleaning.

Material

All extruded aluminum shall be 6063 alloy with a minimum T-5 temper. The thickness of the section varies from 0.150 at web section to .0110 on non-bearing wall surfaces. Glazing gaskets shall be EPDM elastomeric extrusions.

Finish

Both anodized and painted sections are available. All intergral colour anodizing is Architectural Class II., 0.4 to 0.7 mil. coating. A fluoropolymer paint coating conforming to the requirements of AAMA 603 and AAMA 605 specifications, the toughest coating in the industry standards.

Door panels are constructed from 6063-T5 alloy while the base track is extruded from 6061-T6 alloy and hard coat clear anodized to extend wear and reduces friction from the tandem rollers

Hardware

Hardware for aluminum doors and door frames shall be the entrance manufacturer’s standard:

1. M.S. hook bolt

2. Cylinder

3. Thumbturn

4. Flush finger pulls

5. Tandem Rollers

6. Roller Handles

The locking jamb with the lock cutout is furnished loose. If custom hardware is to be furnished by others, templates and physical hardware must be submitted prior to any fabrication.

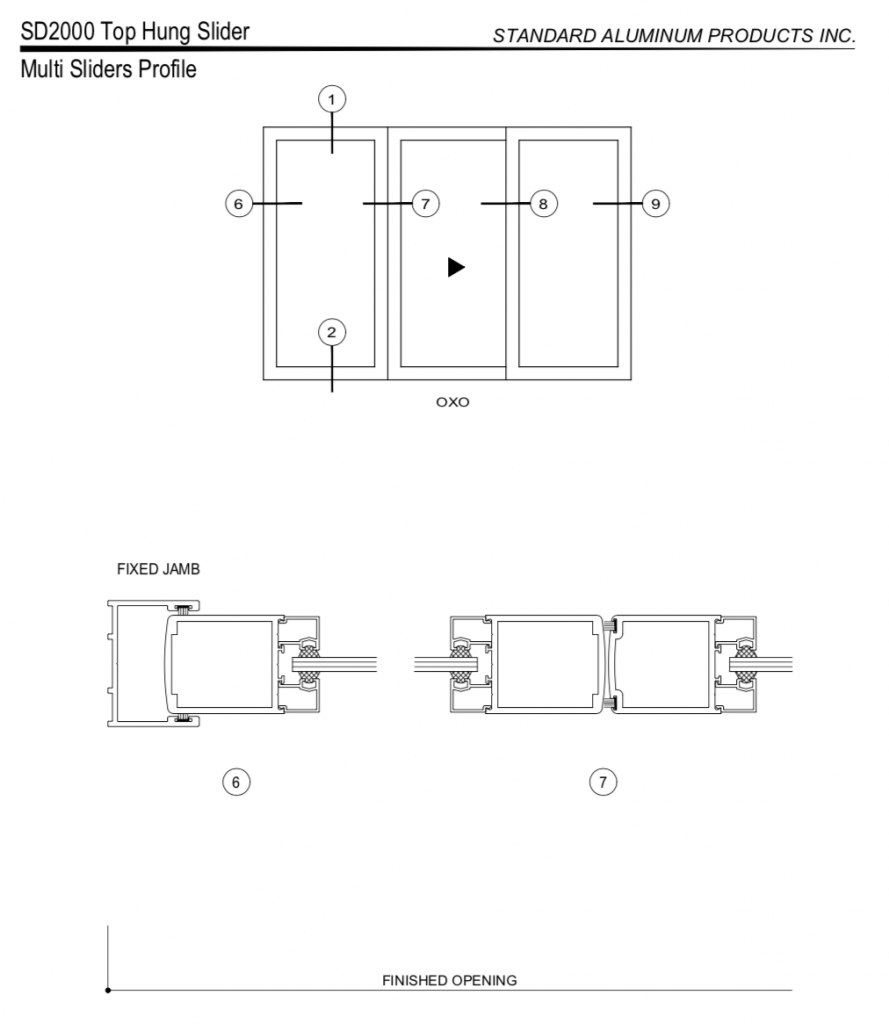

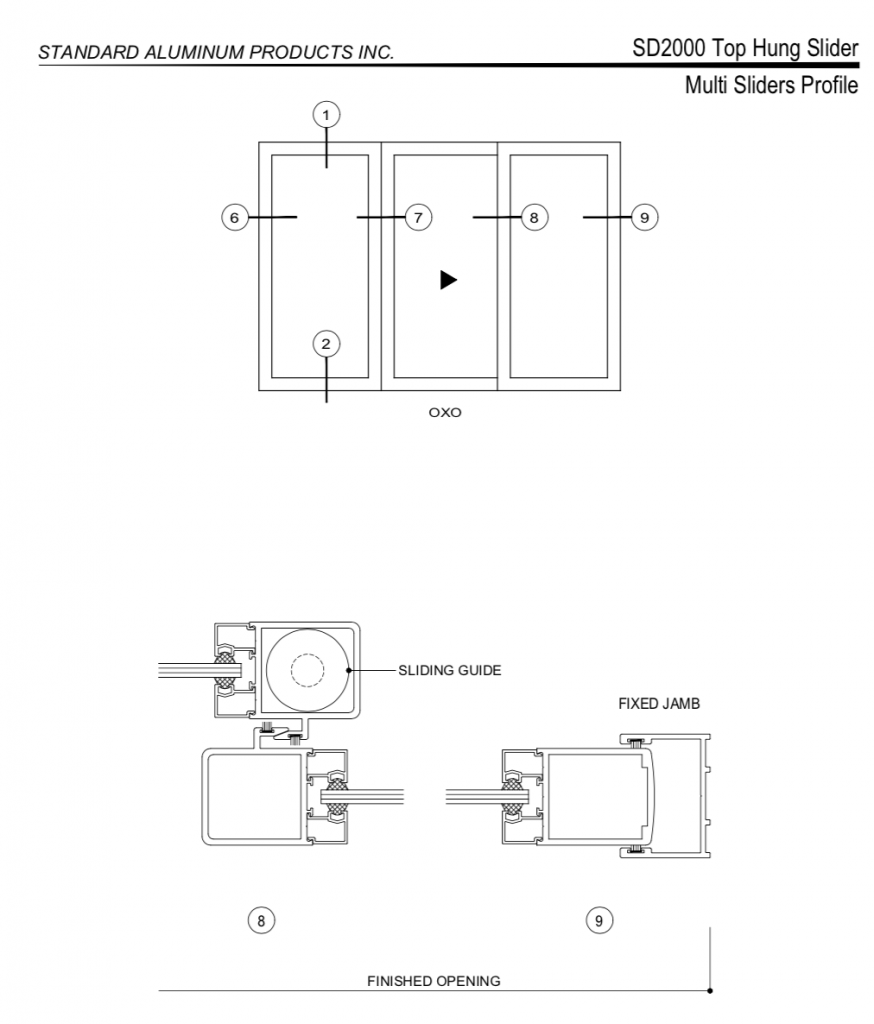

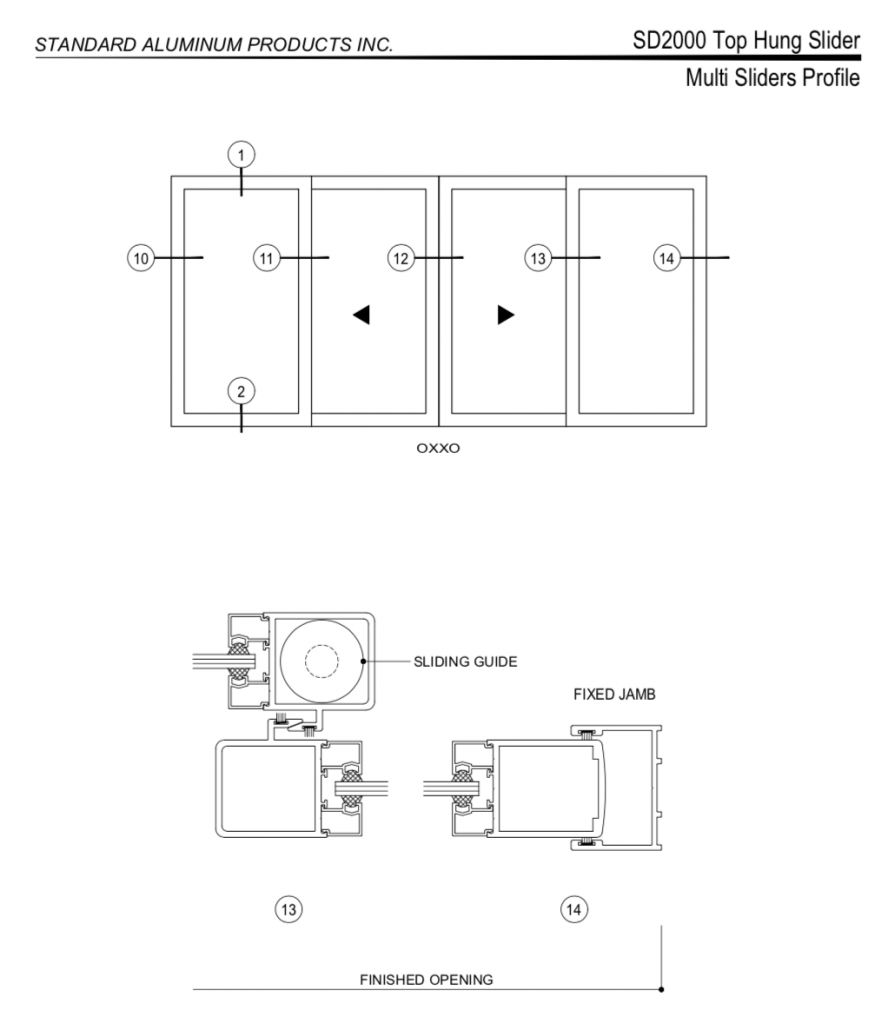

Construction

Standard Aluminum’s SD2000 Series multi track sliding front offers unrestricted design options for easy traffic flow. Multi track units with parallel stacking for a variety of interior applications. Moveable panels can be stacked inline behind a wall, a fixed end panel or an adjacent pocket. The floor track may be either recessed or surface applied. Each sliding door panel has two tandem steel rollers to provide easy operation and longevity. All doors and components are either manufactured or assembled by our trained and experienced technicians.

Performance Requirements

Ideally suited for show rooms, shopping malls and office buildings. The SD2000 has been used in high-end residential applications where a more substantial sliding door is required. For this application additional weather stripping is applied to the sill. he SD2000 is generally assembled with the sliding panel to the inside but can be made with the sliding panel to the outside with additional sill weathering when required.

Optional Accessories

Many options are available to the designer such as:

1. Egress Door

2. Muntins and Panels

3. Higher Base Rail

Protection and Cleaning

After installation the general contractor should adequately protect the exposed aluminum and glass surfaces from damage by others trades. i.e. (but not restricted to) cement splash and leach, grinding, polishing compounds, plaster, paint, lime, acids and other contaminants.