Design

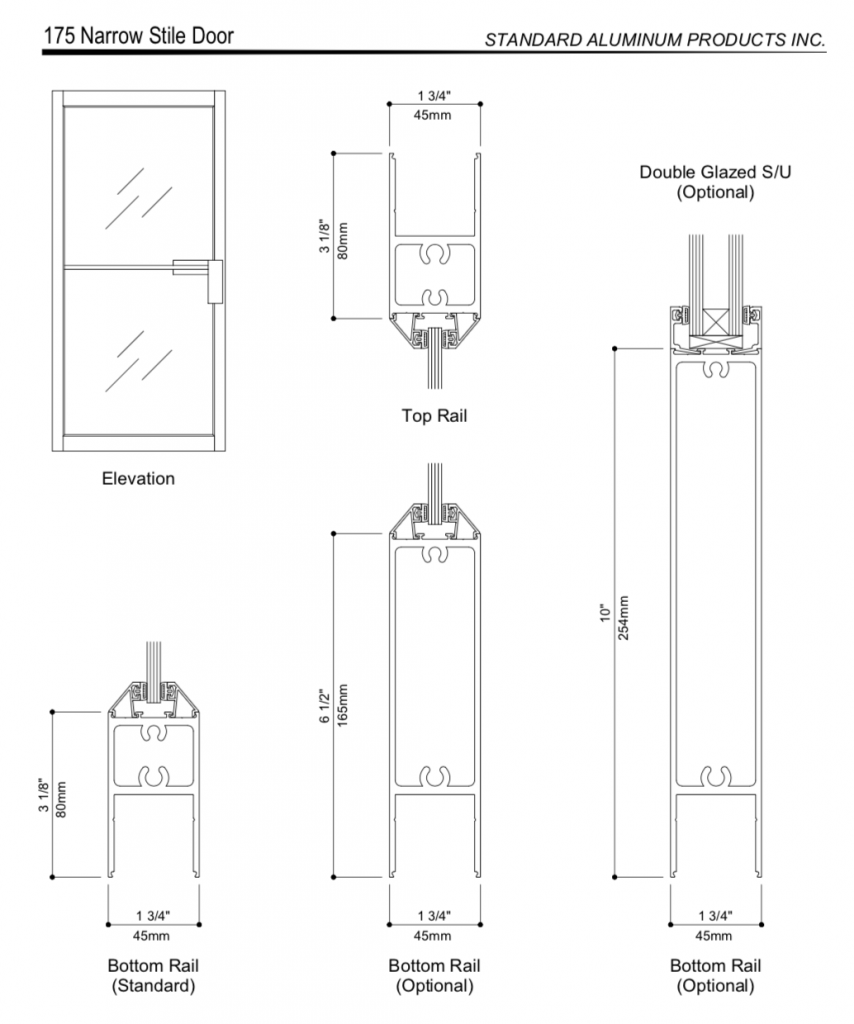

Door Thickness 1.75 inch

Stile Width 2.00 inch

Top Rail Height 3.125 inch

Bottom Rail Height 3.125 inch

Glass stops available;

- Bevelled Single Glazing

- Square Single Glazing

- Sealed Unit Glazing

Hardware

Hardware for aluminum doors and door frames shall be manufacturer’s standard. Hardware for doors shall be;

- Pivoting hinges

- Offset pivots

- Continuous Gear hinges

- Butt hinges

- Lock type

- Closer

- Exit Device

- Push/pull handles

- Threshold

- Miscellaneous glazing

Standard Aluminum uses hardware designed and engineered for aluminum entrance doors by recognized hardware manufactures such as Adams Rite, and Dorma Door Controls. Door weather strip shall be supplied by the door manufacturer. If custom hardware is to be furnished by others, templates and physical hardware must be submitted prior to any fabrication.

Special Features

All doors have snap in glass setting blocks for either single or double glass. M.S. hook lock b.s. is 1.125 inches to give maximum clearance from door framing material. All horizontal sections are extruded 0.03 narrower than vertical sections to assure not only an accurate fit but a clean joint, free of unsightly saw cut lines.

Optional Accessories

In addition to standard push/pull type hardware Standard Aluminum offers a line of;

- Custom handles

- Mid panels

- Muntin bars

- Panic sets

- Offset pivots, spring loaded type, round in appearance and easy to adjust.

- Continuous gear hinges

- Roller bearing butt hinges

- 5 1/2 inch bottom rail

- 6 1/2 inch bottom rail

- 10 inch bottom rail

General Description

Work included; The contractor shall furnish all necessary materials, labour and equipment for the complete installation of aluminum entrance doors, door frames and hardware as detailed on the drawings and specified herein.

Work not included; Structural support for the framing system, wood framing, structural steel, masonry and final cleaning.

Construction

All corners shall be mechanically fastened using plated 3/8 threaded rods secured into an extruded race in the rail section; all fasteners used shall be plated. Corner construction shall remain flexible and not break or tear when a full size x door is over stressed in a direction normal to the plane of the doors, as when the doors is slammed against a floor mounted stop or immovable object. All doors and components are either manufactured or assembled by our trained and experienced technicians.

Material

All extruded aluminum shall be 6063 alloy with a minimum T-5 temper. The thickness of the section varies from 0.150 at web section to .0110 on non-bearing wall surfaces. Glazing gaskets shall be EPDM elastomeric extrusions.

Finish

Both anodized and painted finishes are available. All integral colour anodizing is Architectural Class II., 0.4 to 0.7 mm coating. A fluropolymer paint coating conforming to the requirements of AAMA 2603 and AAMA 2605 specifications, the toughest coating in the industry standards.

Testing

All testing shall be on full size door and frame sections. Air infiltration shall be tested in accordance with ASTM-Designation E283-91 or ASHRAE standards #90-80. Single doors shall not exceed .50 CFM per lin.ft. of perimeter. Pairs of doors shall not exceed 1.0 CFM per lin.ft. of perimeter.

Protection and Cleaning

After installation the general contractor should adequately protect the exposed aluminum and glass surfaces from damage by other trades. i.e.(but not restricted to) cement splash and leach, grinding, polishing compounds, plaster, paint, lime, acids, and other contaminants.